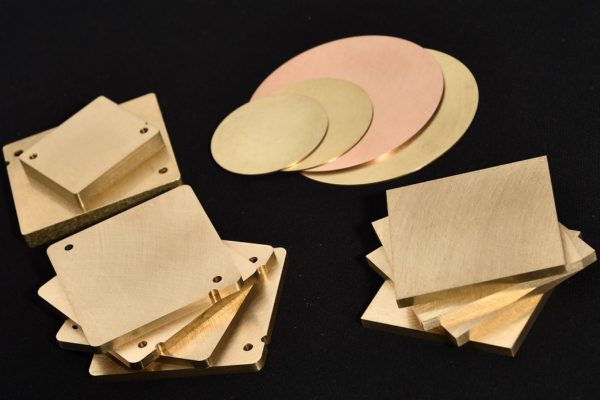

In 2011, the Schaffhausen Industrial and Technological Center (ITS) approached us on behalf of a manufacturer. They were looking for a company independent from the watch industry to find a solution to manufacture Barquettes in such a way that the blanks remain as flat as possible, during and after processing (even with significant one-sided weakening). The scrap rate had to be reduced and expensive refinishing almost eliminated.

That was our entry point into the production of Barquettes for the watch industry. We are proud to have some of the most well-known manufacturers as our clients and strive to always achieve complete satisfaction with our products.