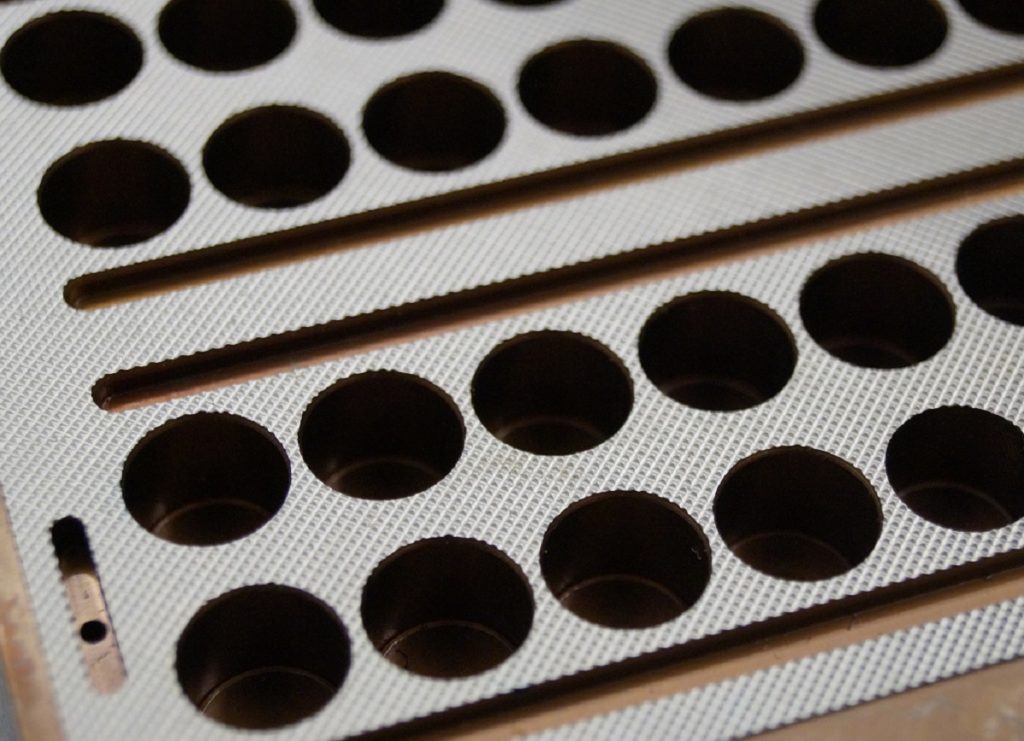

Grinding is used for fine tuning and finishing workpieces. The workpieces can be clamped on our high quality Mägerle machines using a magnetic clamping plate, a vacuum table or mechanical clamping systems as well as zero point clamping systems such as Erowa.

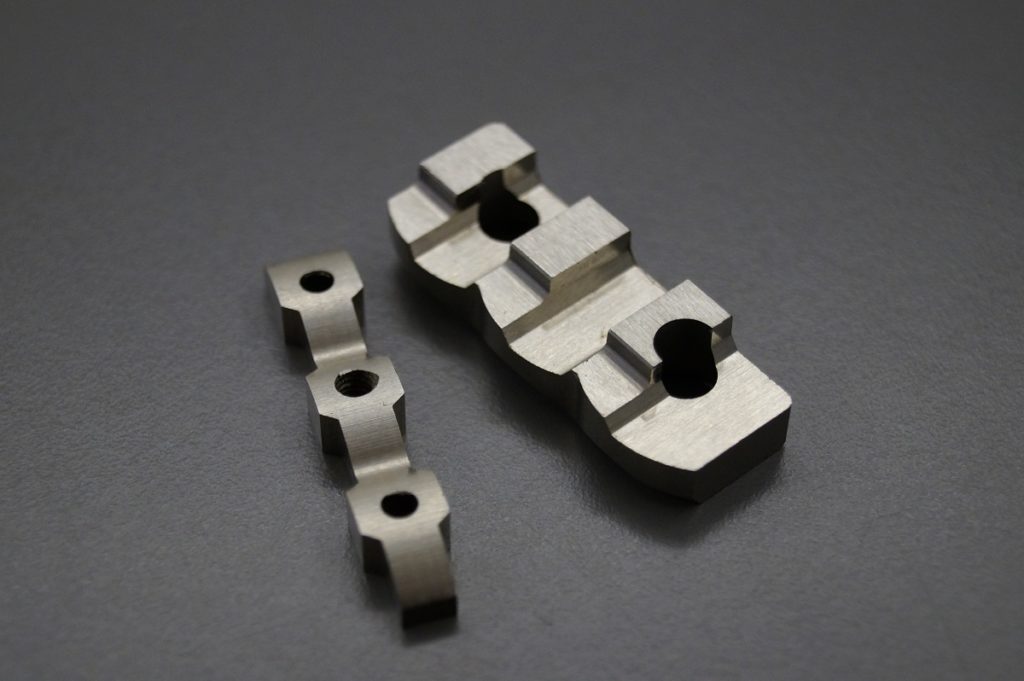

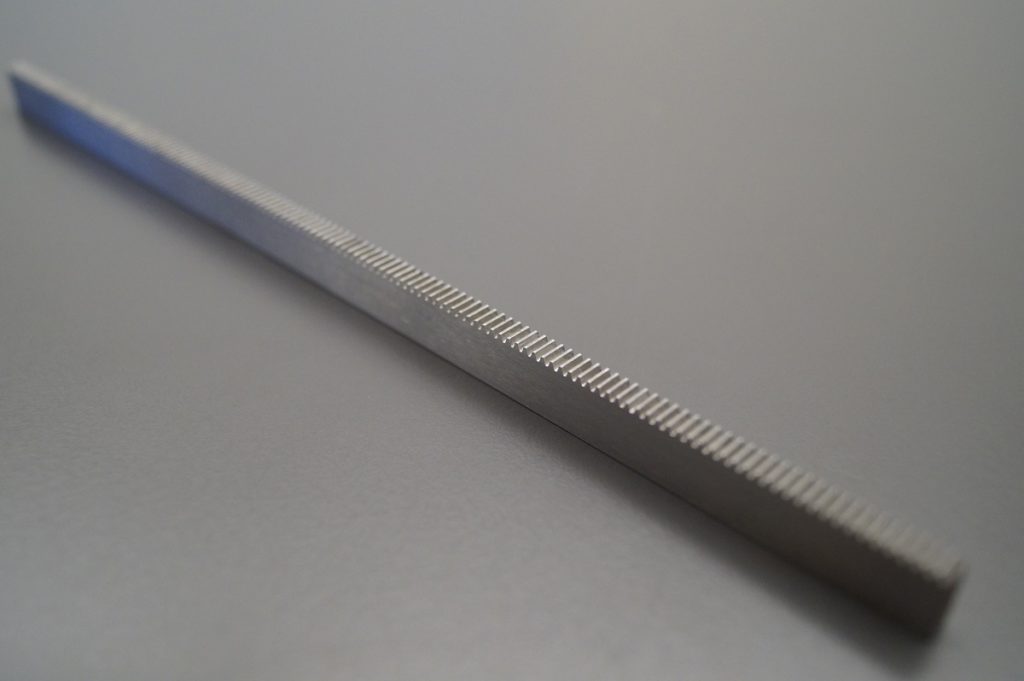

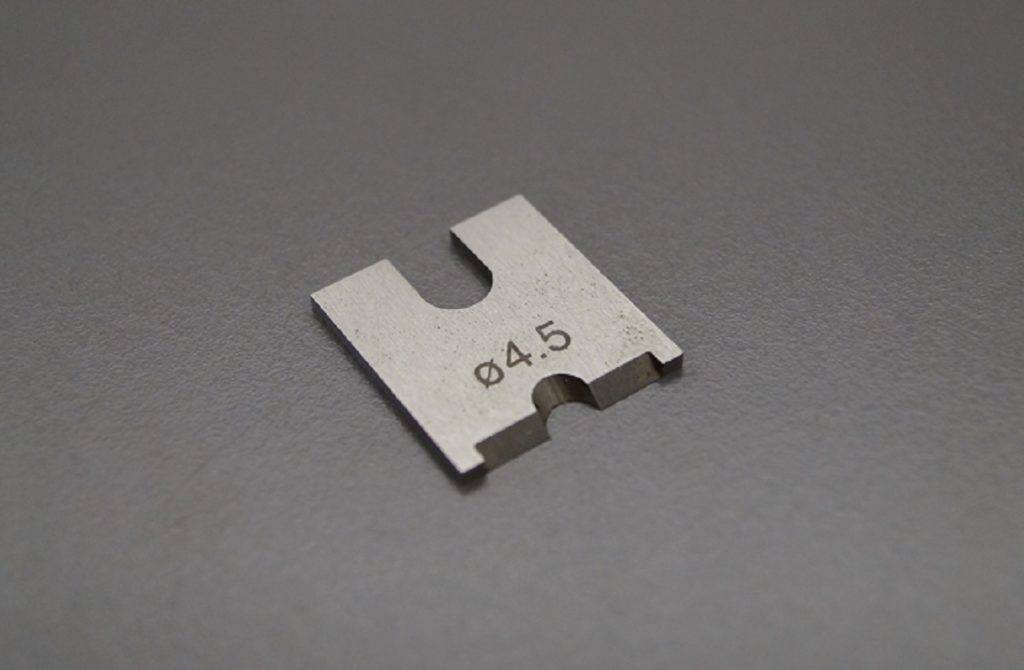

Depending on the type of components to be machined, the pendulum grinding method, plunge pendulum grinding or grinding in the creeper method are used. Various factors play a role, such as the type of grinding wheel, the correct cooling, as well as the type of material and its condition. The surface and accuracy requirements are also crucial.